Hallufix Healthy Shoes

Ginkgo / 2010

Manufacturer

Hallufix GmbH, Munich, Germany

Product Design / Implementation

die:haptiker GmbH

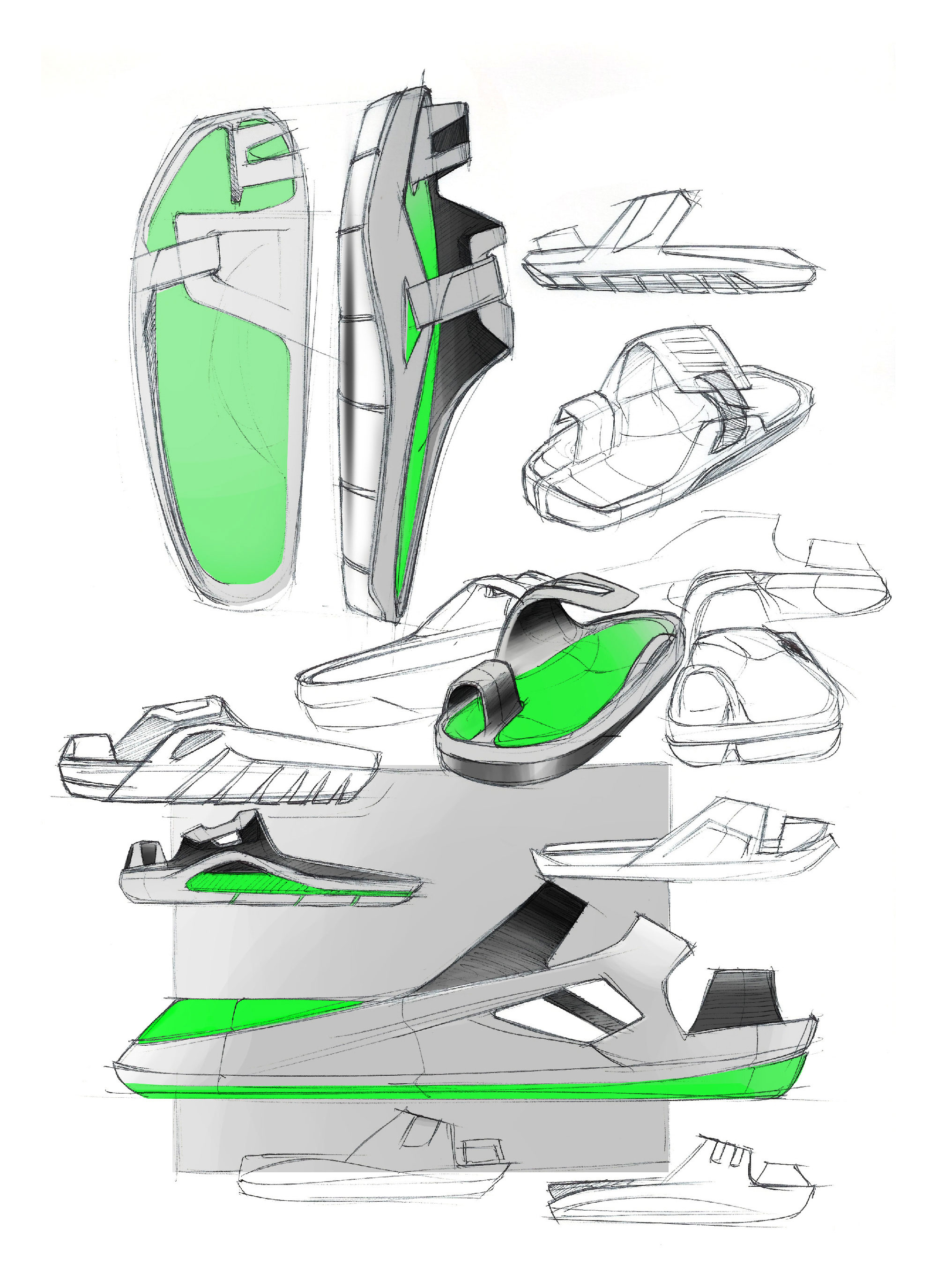

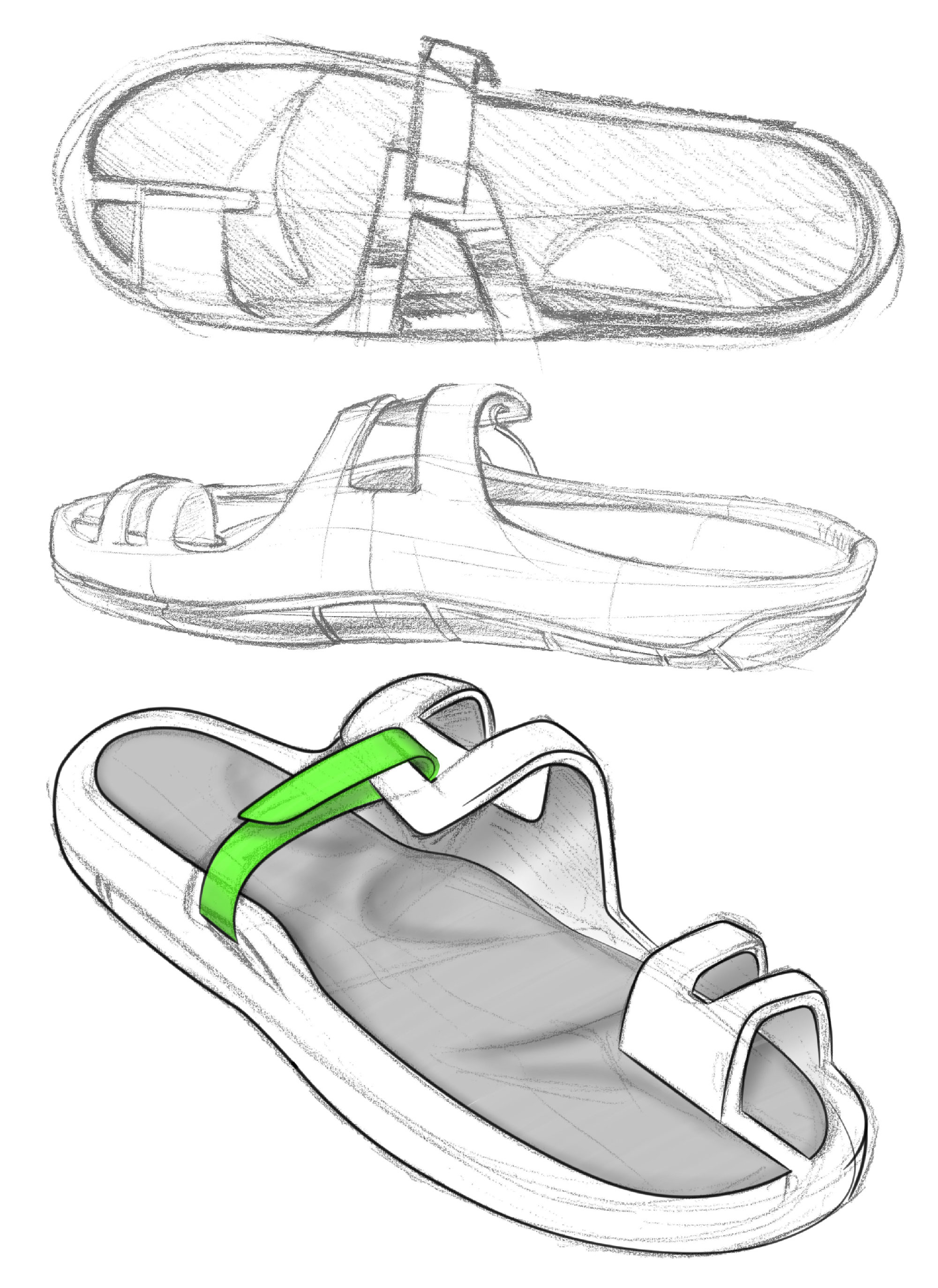

Healthy shoes for healthy feet

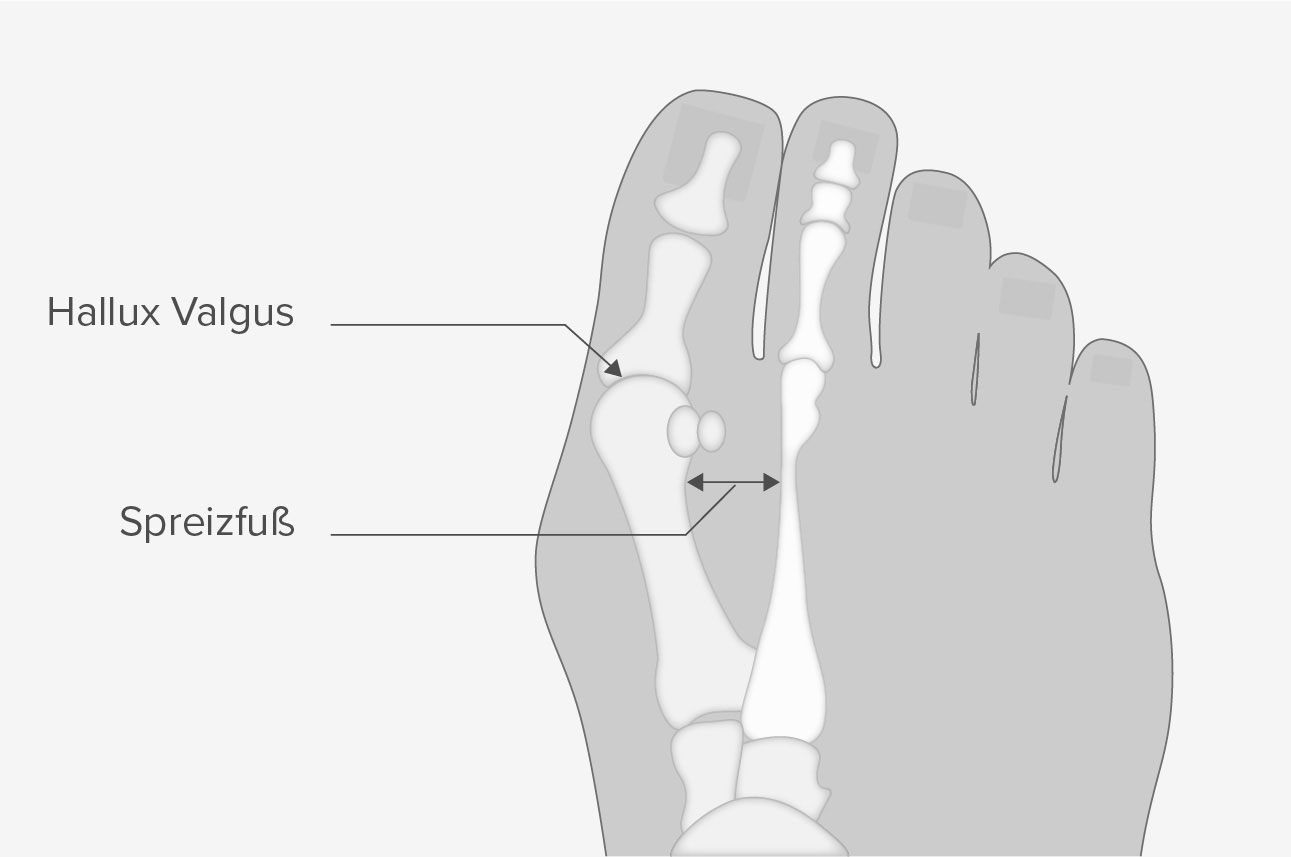

Quote from Hallufix: Around 10 million Germans suffer from Hallux valgus (bunions). Now, there is a solution that also looks really good. Healthy shoes by Hallufix. The painful bunion is corrected and alleviated. Trendy design combined with orthopaedic high-tech, specially shaped footbed, special bandage design: the foot is brought into its natural position and the bunion is corrected. The shoe with a health benefit.”

Designers ask themselves the following questions: Must orthopaedic products look the way they do? At the start of the project, it was clear that this was about “healthy shoes”, which would positively counteract the painful bunion. The designers’ work led to the emergence of a product that reconciles aesthetics, an appealing design and the demanding orthopaedic specifications of the bandage design.

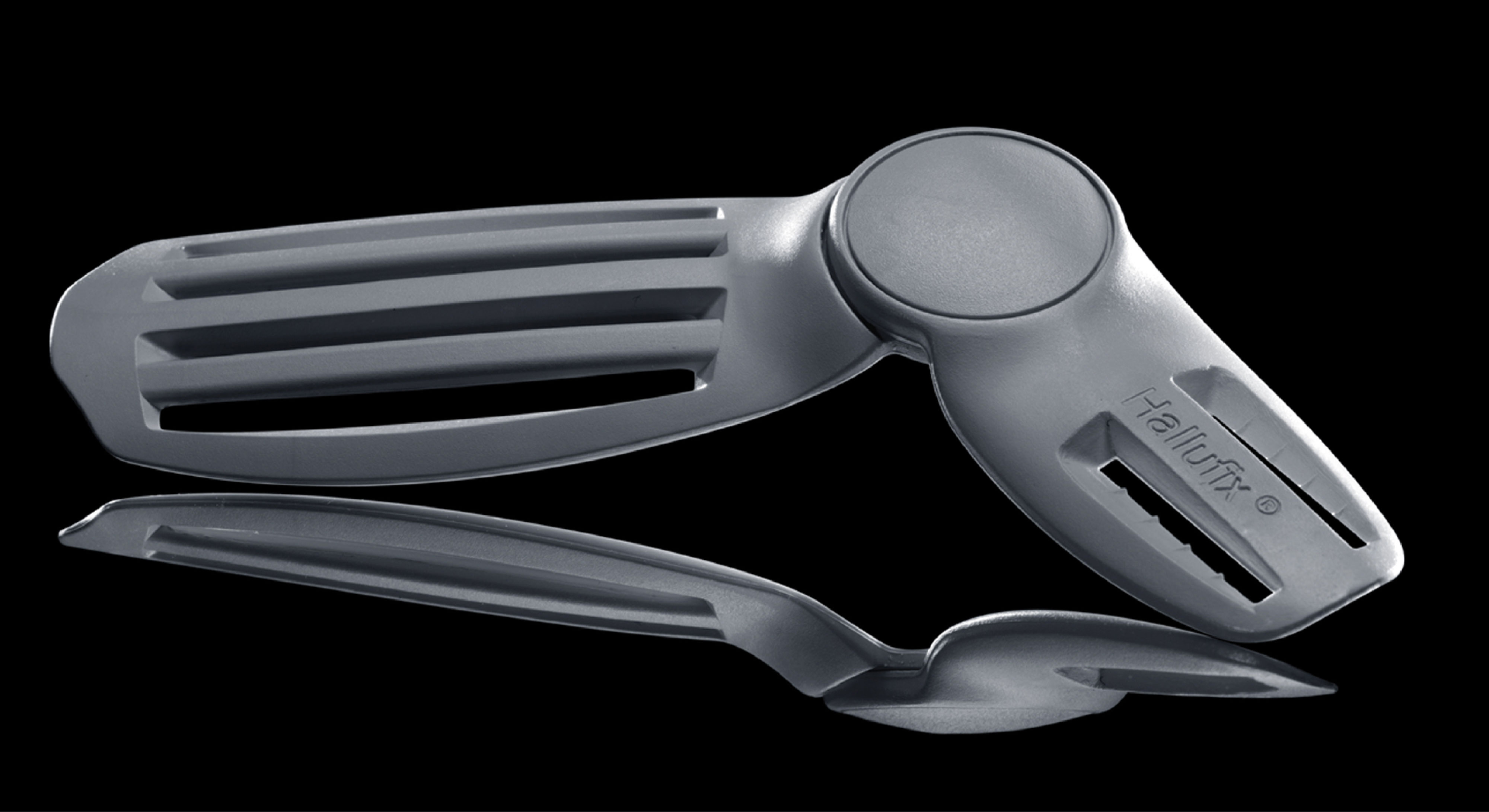

BUNION AID SPLINT

Protection and correction of feet affected by Hallux Valgus / 2004

Manufacturer

Hallufix GmbH, Munich, Germany

Industrial Design

die:haptiker GmbH

Design that supports

Quote from Hallufix: “The Hallufix® splint was developed by scientists and orthopaedists but alleviate pain and correct deformities of the big toe caused by “Hallux valgus”. This joint splint has been proven to correct toe deformities, protects and relieves the painful bunion and supports the entire foot while walking. The splint is easy to apply and can be work on the left or the right. The particular advantage of Hallufix: Unlike regular, rigid bunion night splints, this patented splint system can be worn during the day under load (while walking). The natural flexibility of the base joint of the big toe is maintained while wearing the splint due to an integrated joint next to the bunion. And: The splint’s flat design means that it fits easily into almost any running shoe with a wide forefoot.”

We developed the splint together with orthopaedic and mechanical experts in accordance with orthopaedic specifications. In intensive workshops with the participation of all project partners, we overcame the challenge of designing a splint with a low structure in the area of the joint, which is also comfortable to wear and has a modern design. A particular challenge was, on the one hand, developing the plastic hinge, which needed to function without using secondary materials and without a so-called slip-stick effect and, on the other hand, its fragile form, which, nevertheless, had to withstand all the breaking tests. Outcome: The product has been successfully marketed since its launch in 2004!